Maximizing Efficiency with BTEX Elimination Systems!

3 min read

In industries where volatile organic compounds pose environmental and health risks, the implementation of effective elimination systems is paramount. Among these compounds, benzene, toluene, ethylbenzene, and xylene (BTEX) are particularly concerning due to their toxicity and prevalence in various industrial processes. Maximizing efficiency in BTEX elimination systems not only mitigates environmental impact but also ensures regulatory compliance and fosters a safer working environment. This article explores the significance of BTEX elimination systems and strategies to enhance their efficiency.

Understanding BTEX Compounds:

Benzene, toluene, ethylbenzene, and xylene are aromatic hydrocarbons commonly found in industrial activities such as petroleum refining, chemical manufacturing, and printing. While indispensable to these processes, BTEX compounds pose significant health risks, including carcinogenicity and neurological effects, even at low concentrations. Additionally, their volatility makes them prone to dispersion in the atmosphere, contributing to air pollution and environmental degradation.

Challenges in BTEX Elimination:

The removal of BTEX compounds from industrial emissions presents several challenges. Traditional methods like adsorption, absorption, and thermal oxidation can be effective but may suffer from limitations such as high energy consumption, operational complexity, and generation of secondary pollutants. Furthermore, variations in BTEX concentrations and composition across different industrial processes necessitate tailored solutions for each application.

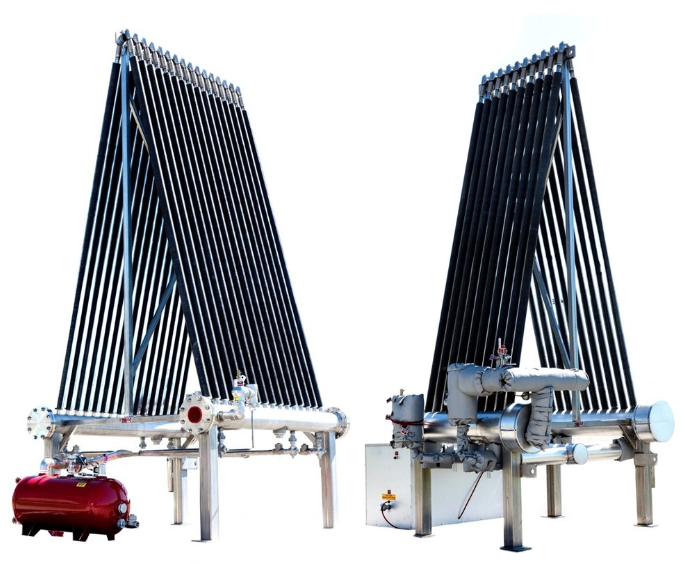

Maximizing Efficiency through Advanced Technologies:

Advancements in pollution control technologies have led to the development of innovative BTEX elimination systems that prioritize efficiency, reliability, and sustainability. One such approach is catalytic oxidation, which utilizes catalysts to promote the conversion of BTEX compounds into less harmful byproducts like carbon dioxide and water vapor. Catalytic oxidation offers several advantages, including lower operating temperatures, reduced energy consumption, and minimal generation of secondary pollutants.

Another promising technology is biofiltration, which harnesses the metabolic activity of microorganisms to biodegrade BTEX compounds into harmless substances. Biofiltration systems are cost-effective, environmentally friendly, and suitable for treating large volumes of contaminated air. By optimizing operating conditions and selecting appropriate microbial species, biofilters can achieve high removal efficiencies across a wide range of BTEX concentrations and flow rates.

Additionally, membrane separation techniques such as pervaporation and membrane distillation have shown potential for selectively removing BTEX compounds from gas streams. These methods rely on semi-permeable membranes to selectively permeate BTEX molecules while excluding other components, enabling the concentration and recovery of valuable products from industrial emissions.

Integration and Optimization:

To maximize the efficiency of BTEX elimination systems, integration with existing processes and optimization of operational parameters are essential. By conducting thorough engineering assessments and performance evaluations, engineers can identify opportunities for system optimization, including the selection of suitable equipment, adjustment of process conditions, and implementation of advanced control strategies.

Furthermore, continuous monitoring and real-time data analysis enable proactive maintenance and troubleshooting, ensuring optimal performance and reliability over time. Advanced sensor technologies, remote monitoring systems, and predictive analytics empower operators to detect potential issues early, minimize downtime, and optimize resource utilization.

Regulatory Compliance and Environmental Stewardship:

In addition to efficiency and cost-effectiveness, regulatory compliance and environmental stewardship are critical considerations in the design and operation of BTEX elimination systems. Adherence to local, national, and international regulations governing air quality, emissions standards, and occupational health is non-negotiable. By staying abreast of evolving regulatory requirements and adopting best practices in pollution control, industries can uphold their social responsibility and earn public trust.

Furthermore, proactive engagement with stakeholders, including government agencies, environmental organizations, and local communities, fosters transparency, collaboration, and shared accountability. By soliciting feedback, addressing concerns, and implementing sustainable practices, industries can demonstrate their commitment to environmental stewardship and build mutually beneficial relationships with stakeholders.

Conclusion:

Maximizing efficiency in BTEX elimination systems is essential for safeguarding human health, protecting the environment, and ensuring regulatory compliance in industrial operations. By leveraging advanced technologies, optimizing system integration, and prioritizing environmental stewardship, industries can achieve significant reductions in BTEX systems while enhancing operational efficiency and sustainability. Through collaboration, innovation, and a commitment to excellence, we can pave the way towards a cleaner, safer, and more sustainable future for generations to come.