Ensuring Safety: Understanding Sterile Packaging in Healthcare

4 min read

Sterile packaging plays a critical role in maintaining the safety and integrity of medical products in the healthcare industry. This article explores its significance and role in safeguarding patients’ health and well-being.

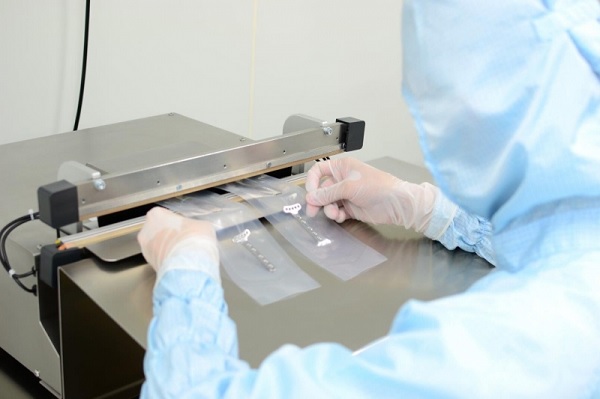

Understanding Sterile Packaging

Sterile packaging refers to the materials and processes used to package medical products in a sterile environment, ensuring that they remain free from contamination by microorganisms. These packaging solutions are essential for medical devices, implants, and certain medications that require a environment to prevent infections and ensure patient safety.

The Importance of Sterile Packaging

Sterile packaging serves several key functions in the healthcare industry:

1. Infection Prevention: It helps prevent infections by maintaining the sterility of medical products, reducing the risk of contamination during storage, transportation, and use.

2. Enhancing Patient Safety: It ensures optimum patient safety, by ensuring that medical products remain free from harmful microorganisms, patients can undergo medical procedures and treatments with confidence, knowing that the risk of adverse effects is minimized. This aspect of sterile packaging not only contributes to physical well-being but also promotes peace of mind for both patients and healthcare providers.

3. Advanced Sterilization Techniques: As technology continues to advance, so do sterilization techniques used in the healthcare industry. It is worth delving into the latest innovations in sterilization processes, such as gamma irradiation, ethylene oxide sterilization, and hydrogen peroxide vapor sterilization. Exploring these techniques can provide insights into how this form of packaging adapts to meet evolving safety standards and regulatory requirements.

4. Environmental Considerations: While sterile packaging primarily focuses on maintaining product integrity and safety, it is also essential to consider its environmental impact. Discussing sustainable packaging solutions and initiatives within the healthcare sector can highlight efforts to reduce waste, minimize resource consumption, and explore biodegradable materials. This broader perspective underscores the interconnectedness of healthcare practices with environmental stewardship.

5. Global Perspective: Packaging practices, especially the ones sterile in nature, vary across different regions and healthcare systems worldwide. Examining international standards and approaches can offer valuable insights into best practices and potential areas for improvement. Comparing and contrasting regulatory frameworks and cultural attitudes can enrich the discussion and provide a more comprehensive understanding of its significance on a global scale.

6. Emerging Challenges and Solutions: Despite significant advancements, packaging done in a sterile environment still faces challenges such as maintaining sterility in complex medical devices or ensuring compatibility with emerging healthcare technologies. Exploring these challenges and the innovative solutions being developed to address them can shed light on its dynamic nature and its ongoing evolution within the healthcare landscape.

7. Product Integrity: Packaging done in a sterile environment helps preserve the integrity and efficacy of medical products by protecting them from environmental factors such as moisture, light, and temperature fluctuations that could compromise their quality.

Types of Sterile Packaging

Pouches and Wraps: Sterile pouches and wraps are commonly used to package medical devices and implants, providing a barrier against contamination and maintaining sterility until the product is ready for use.

Trays and Containers: Sterile trays and containers are used to package surgical instruments and other medical devices for use in operating rooms and other clinical settings. These containers withstand sterilization processes such as auto-claving while maintaining sterility.

Sterile Barrier Systems: Sterile barrier systems consist of multiple layers of packaging materials, including pouches, wraps, and containers, designed to maintain the sterility of medical products during storage and transportation.

Sterile Packaging Accessories: Accessories such as adhesive labels, indicator strips, and sterilization pouches packaged in a sterile environment, are used to ensure that medical products remain sterile until they are ready for use.

Best Practices for Sterile Packaging

Use of Cleanroom Facilities: Packaging done in cleanroom facilities equipped with high-efficiency particulate air (HEPA) filtration systems minimize the risk of contamination.

Validation of Sterilization Processes: Sterile packaging materials should undergo validation of sterilization processes to ensure that they effectively eliminate microorganisms and maintain sterility throughout the product’s lifecycle.

Inspection and Quality Control: Such materials should undergo rigorous inspection and quality control measures to detect any defects or inconsistencies that could compromise sterility.

Proper Handling and Storage: These materials should be handled and stored according to manufacturer guidelines to prevent damage and ensure that they remain sterile until they are ready for use.

Conclusion

Sterile packaging is a critical component of the healthcare industry, ensuring the safety and integrity of medical products and protecting patients from infections and other adverse effects. By maintaining sterility throughout the packaging process, such packaging helps uphold the highest standards of quality and safety in healthcare delivery. As the healthcare industry continues to evolve, will remain an essential element in safeguarding patient health and well-being.